- Home

- About Us

- Products

-

Solenoid Valve

- Pilot Operated Diaphragm Valve (NC)

- Pilot Operated Diaphragm Valve (NO)

- Semi Lift Diaphragm Operated Solenoid Valve Normally Closed

- Pulse Jet Angle Type Dust Collector Valve

- Pilot Operated Piston Type Steam Valve (NC/NO)

- Semi Lift Diaphragm Operated Solenoid Valve Normally Open

- Gas Solenoid Valve

- Pilot Operated Diaphragm Type Solenoid Valve (NC)

- 2/2 Way Direct Acting Valve (NC/NO)

- 3/2 Way Direct Acting Valve (NC)

- 2/2 Solenoid Valve For Terminal / Gantry Automation (NC / NO)

- 2 Way Direct Acting Media Separaeted Solenoid Valve (Normally Close)

- 2/2 Way Direct Acting Auto Drain Solenoid Valve (Normally Close)

- Pinch Type Solenoid Valve (Normally Close / Open)

- 2/2 Way Control Valve With Aluminum Operator (Normally Close)

-

Pneumatic Valves

- 4X2 Double Solenoid Valve

- 3/2 Single Solenoid Valve With Spring Return (NC/NO)

- 3/2 Double Solenoid Valve

- 5/2 Single Solenoid Valve With Spring Return

- 5/2 Double Solenoid Valve

- 5/3 Double Solenoid Valve With Spring Center

- 3/2 , 5/2 Single Solenoid Namur Valve With Spring Return

- 3/2 , 5/2 Double Solenoid Namur Valve

- 3/2 Hand Lever Valve

- 5/2 Hand Lever Valve

- 5/3 Hand Lever Valve Manual Return

- 5/3 Hand Lever Valve Spring Return

- 3/2 Single External Pilot Operated Valve With Spring Return (NC / NO)

- 3/2 Double External Pilot Operated Valve

- 5/2 Double External Pilot Operated Valve

- 5/3 Double External Pilot Operated Valve With Spring Center

- 3/2 Push Pull Valve

- 5/2 Push Pull Valve

- Manifold For DCV Series

- Angle Seat Valves

- Pneumatic Actuator

- Ball Valve

-

Butterfly Valve

- Hand Lever Operated Wafer Type Butterfly Valve

- Pneumatic Operated Wafer Type Butterfly Valve - PN10

- Pneumatic Operated Wafer Type Butterfly Valve - PN16

- Gear Box Operated Wafer Type Butterfly Valve

- Hand Lever Operated Lug Type Butterfly Valve

- Pneumatic Operated Lug Type Butterfly Valve - PN10

- Pneumatic Operated Lug Type Butterfly Valve - PN16

- Gear Box Operated Lug Type Butterfly Valve

- Solenoid Coil

- Solenoid Proportional Flow Control Valve

- Limit Switch

- Roto Seal Coupling

-

Poppet Valve

- 3/2 Single Solenoid Poppet Valve (Normally Close)

- 5/2 Single Solenoid Directional Control Poppet Valve (Monostable)

- 3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable)

- 5/2 Double Solenoid Directional Control Poppet Valve (Bistable)

- 3/2 Single Solenoid Directional Control Poppet Valve (Normally Close)

- 3/2 Single Solenoid Namur Poppet Valve (Normally Close)

- 3 Way Direct Acting Namur Poppet Type Valve

- 3 Way Direct Acting Poppet Type Valve

- 3 Way Direct Acting Poppet Type Valve (Universal)

- 5x2 Double Solenoid Directional Control Hybrid Poppet Valve

- 3/2 Single And Dual Pressure Blow Solenoid Poppet Valve (Normally Close)

- Medical Oxygen Equipments

-

One Touch Fittings

- Straight Union

- Different Dia. Straight Union

- Union Elbow Reducer

- Union Elbow

- Union Tee

- Union Tee Reducer

- Union 'Y’

- Union 'Y' Reducer

- Cross Union

- Male Connector

- Female Connector

- Flow Control - R Series

- Flow Control - M Series

- Plug

- Bulk Head Union

- Bulk Head Female Connector

- Male Elbow

- Female Elbow

- Male Branch Tee

- Female Branch Tee

- Female Run Tee

- Male Run Tee

- Male Branch Y

- Polyurethane Tubes

-

Air Cylinder

- Pneumatic Tie Rod Cylinder (As Per ISO 15552 / VDMA 24562 Standards)

- Pneumatic Tie Rod Cylinder (As per ISO 6431 / CETOP RP43P, RP53P standards)

- Pneumatic Cylinder Double End Double Acting (As Per ISO 15552 / VDMA 24562 Standards)

- Pneumatic Profile Cylinder - Square Type (As Per ISO 15552 / VDMA 24562 Standards)

- Pneumatic Profile Cylinder Double End Double Acting - Square Type (As Per ISO 15552 / VDMA 24562 Standards)

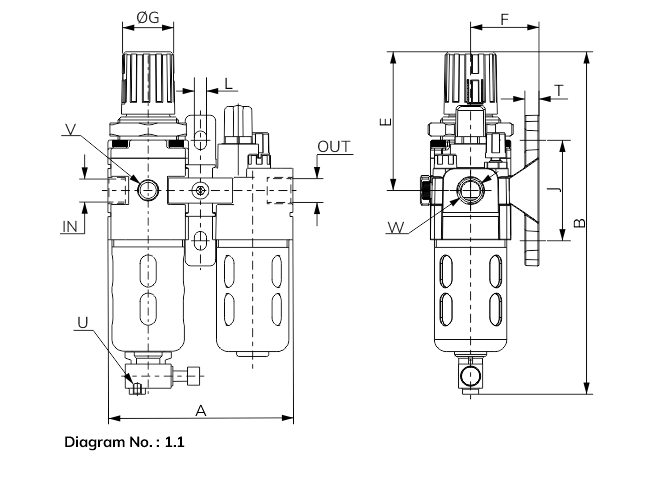

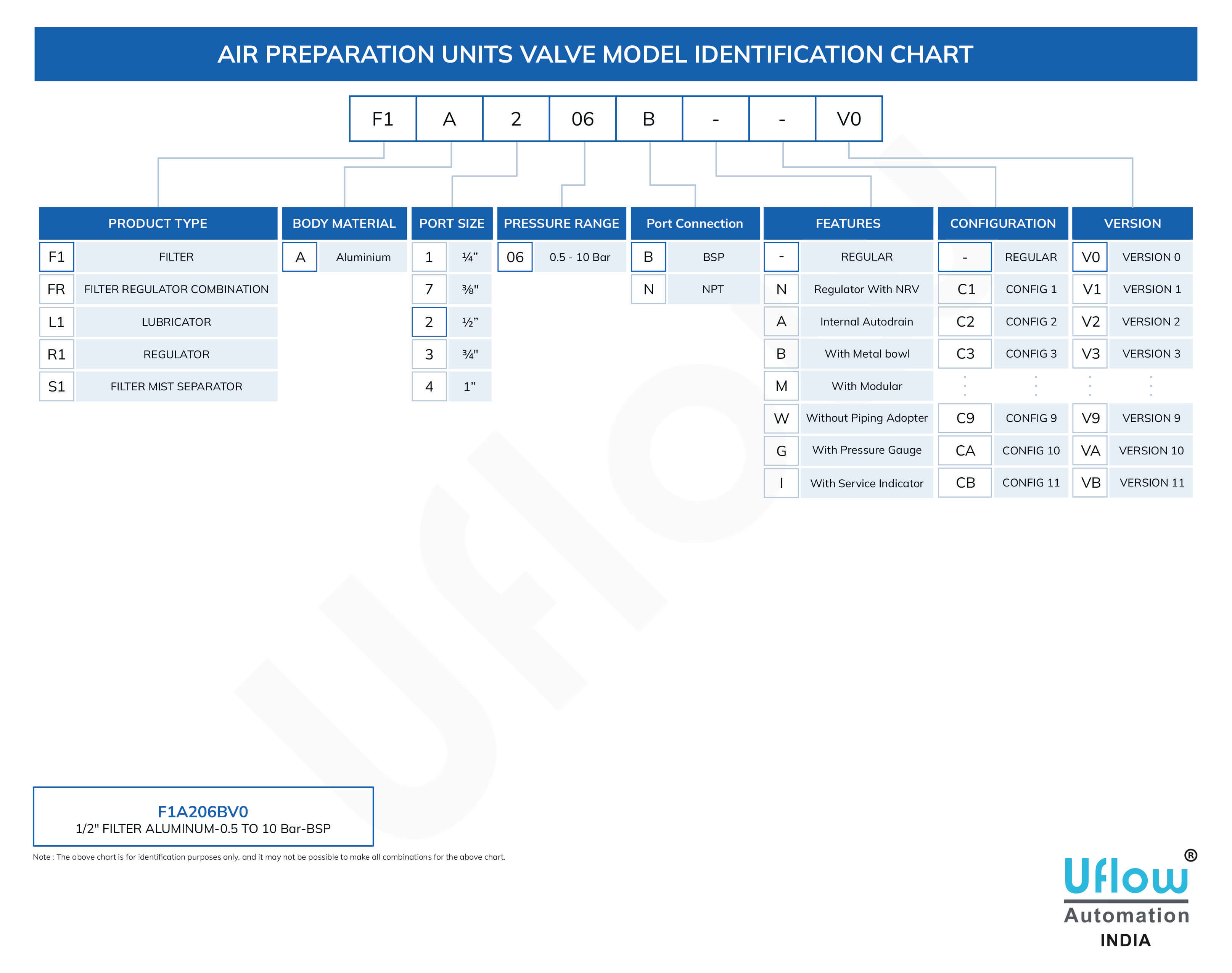

- Air Preparation Unit

- Irrigation

-

Solenoid Valve

- Tech Info

- Certification

- Reach Us

- Career

- Covid-19 Supplies